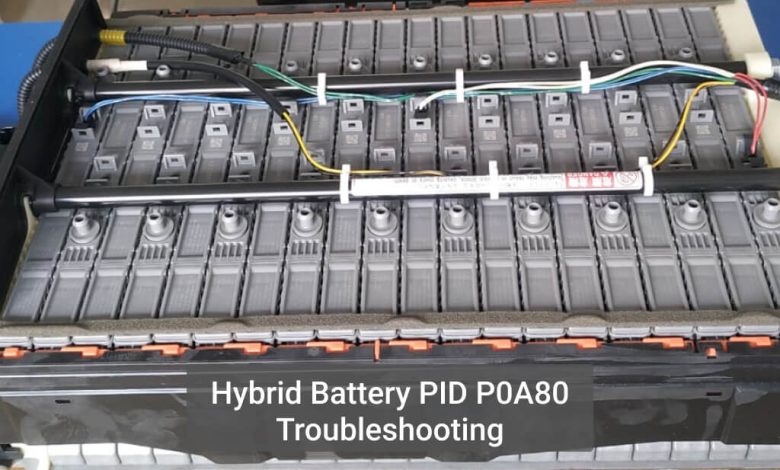

Hybrid Battery PID P0A80 Troubleshooting.

Let’s see how to diagnose & pin point Gen 3 PRIUS P0A80 code – Replace Battery Pack!

Hybrid systems are recent adoption in Automobiles and are under continuous development worldwide. So the detailed information of repair, operation conditions, failure, troubleshooting is rarely available. The newer the vehicle the less likely available these useful information’s. Most of the cases you have a symptom chart with a long flow chart and your faulty vehicle as reference. Sometimes you have to choose your own diagnostic path for hybrid systems that you are not worked on before. The best way to get knowledge on hybrid cars is reading properties and working principle of hybrid components again & again. This will build your confidence and reduce anxiety.

This code is also called “The End of Life” but it may appear with some other correlative codes too, like coolant leakage thermal control or battery management system.

Unless you have some other codes along with a P0A80, this code will almost certainly result in battery replacement. However, if you still want to verify and document the fault, you may actually find something else, but mostly Battery age is the most common root cause of this. There are multiple ways to verify the fault, and none of them take very long time. For every diagnosis, Manufactures recommends customer interview first for troubles characteristics in car and checking available voltage PIDs at rest, with accessory loads, and during a test drive. Use of Min./Max. voltage and Delta SOC PIDs to isolate the defect.

For gen 3 PRIUS three tests were performed below, which explains the need to look at all available evidence. Great evidence in case is the customer revealed that besides a slight loss of fuel economy, the only symptoms were an intermittent jerking on tip.

Pending (Current) P0A80 PID means the code has detected during last trip that means it’s not likely an intermittent fault and should be easy to duplicate.

Delta SOC Toyota uses the Delta SOC PID as a comparison of the maximum variation in SOC between individual blocks. In Toyota vehicles standard Delta SOC limits from 0 to 20% but over 39.5% delta SOC will result to set a code as shown in screenshot below.

Test Drive & Reverse Stressing Batteries are great way to find a bad block is to use a lot of current during a test drive. The driving conditions that stress the batteries the most are WOT acceleration and hard acceleration in reverse gear. The ICE can’t run in reverse, so it’s a good way to make sure that you’re only using battery power without ICE power or ICE-generated current helping out.

The screen shot below shows the minimum and maximum voltage PIDs along with some block voltage PIDs during a test drive that involved heavy acceleration in both drive and reverse.

The minimum and maximum values for the point of greatest charge state were 17.42 Volts and 17.56 Volts. That is, when the battery was the ‘fullest’, the least charged block was 17.42 Volts and the most charged block was 17.56 Volts. That’s only a 140-mV difference, and while we like to see 100 mV or less, this certainly doesn’t indicate a failed battery.

In the screen shot above the minimum and maximum values for the point of lowest charge state were 15.36 Volts and 15.49 Volts. That’s only a 130-mV difference; so again, these results do not indicate a failed high voltage battery.

Accessory Load Testing 12-Volt loads are a good way to stress a high voltage battery because the current for accessories comes from the high voltage battery through the DC-DC converter. Turn on lights, fans, air conditioning (electric compressor applications) and other accessories, In the screenshot below, the voltage goes low in Ready mode, charges when the ICE is cycled on, and then slowly discharges again. At the lowest charge state, the lowest (minimum) block is 14.63 Volts (block 4 – bottom PID), and the highest (maximum) block is 15.12 Volts. That’s a 490-mV difference. You’ll often see over 1 Volt variation, but it’s enough to set this code. When in doubt, un-Ready the vehicle but place it in ‘Accessory’ mode to prevent the ICE (and MG1 in this case) from charging the battery.

According to Predictive Analysis of PRIUS Hybrid Battery failure, the state of the battery may be derived by the difference between the highest voltage bank and lowest voltage bank.

0.20V = 100% acceptable efficiency

0.45V = 75% acceptable efficiency

0.70V = 50% acceptable efficiency

0.95V = 25% acceptable efficiency

1.20V = 0% acceptable efficiency – bad battery soon to need replacement.

Summary of signs of a traction battery going to die.

- Lackluster or harsh acceleration.

- Abnormally low MPG.

- High Delta SOC. (39+ to 80%)

- Fast charging & fast discharging

- Frequent ICE on & off cycle.

- Min. & Max. cell voltage difference: (For new battery-Max. 0.16V, for good used Max. 0.28V and for bad 1.2V to 3.5V).

- Abnormal noise from engine.

- Abnormal Win & Wout. (Std. for Prius Gen 3 is +/- 20K)

- Low discharge rate between engine on/off cycle remains below 2 minutes. But For new or good battery discharge rate remains 4.5 to 5 minutes.

- High min & max voltage fluctuation, For new battery 15 to 16 volt & for bad battery 14.5 to 18 volts.

Thanks for reading.